PRODUCTS

CONTACT US

TEL: +86-532-85754589,85775618

FAX: E-Mail

E-MAIL: tlead.net@gmail.com; tlead.net@hotmail.com

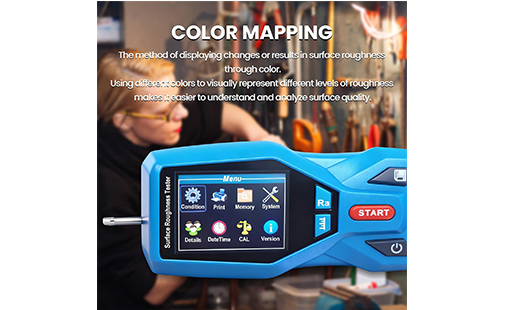

AMT221 Surface Roughness Tester

AMT220 upgrade model, with Bluetooth mode + colorful LCD

Features:

1. Electromechanical integration design, small size, light weight, easy to operation

2. DSP chip control and data processing, high speed, low power consumption

3. 160μm Large measurement range

4. Ra, Rz, Rq, Rt, Rc, Rp, Rv, R3z, R3y, Rz(JIS), Rs, Rsk, Rsm, Rku; Ry(JIS); Rmax, Rmr, RPc, Rk, Rpk, Rvk, Mr1, Mr2

5. 320 x 240 TFT display, digital or graphic highlight IPS display; no viewing angle

6. Automatic range switching and display

7. Real time display of sampled waveform. Display full information, intuitive and graphical displays all parameters

8. TYPE C and Mini USB dual USB interface design for charging, communication, and automatic control

9. Alarm limits that can be set for measurement results

10. Single selection or batch printing of historical records and waveforms

11. Compatible with ISO4287, DIN, ANSI, JIS multiple standards

12. 4 Profile Filter: Gauss, RC, PC-RC, DP

13. Built-in rechargeable battery and control circuit, high capacity, no memory effect

14. There are remaining charge indicator, charging hint

15. Tester has charging instructions, the operator can readily understand the level of charge

16. Can work more than 20 hours while the power is enough

17. Large capacity data storage, can store 100 item of raw data and waveforms

18. Real-time clock setting and display for easy data recording and storage

19. With automatic sleep, automatic shutdown power-saving features

20. Reliable circuit and software design of prevent the motor stuck

21. Instrument can display a variety of information tips and instructions. For example Measurement result display, the menu prompts and error messages

22. Can connected to the computer and printer

23. All parameters can be printed or print any of the parameters which set by the user

24. Optional curved surface pickup sensor, holes sensors, measurement stand, Sheath of sensor, extension rod, printer and analysis software

Specifications:

1. Measuring Range:

1) Ra, Rq: 0.005μm ~ 16μm

2) Rz, R3z: 0.02μm ~ 160μm

3) Ry, Rt, Rp, Rv: 0.02μm ~ 160μm

4) Rsk: 0 ~ 100%

5) Rs, Rsm: 0.02 ~ 1000μm

6) Rmr: 0 ~ 100%

2. Range:

1) The Z axis (vertical): 160μm

2) The X axis (horizontal): 17.5mm/ 0.69"

3. Resolution ratio, The Z axis (vertical):

1) 0.001μm/±20μm

2) 0.002μm/±40μm

3) 0.004μm/±80μm

4. Parameter: Ra, Rz, Rq, Rt, Rc, Rp, Rv, R3z, R3y, Rz (JIS), Rs, Rsk, Rsm, Rmr, Rku; Ry(JIS), Rmax, Rpc, Rk, Rpk, Rvk, Mr1, Mr2

5. Standard: ISO4287, ANSI b46.1, DIN4768, JISb601

6. Graphic: Material ratio curve of the profile, P-Curve, R-Curve

7. Filter: RC, PC-RC, Gauss, D-P

8. The sampling length (lr): 0.25, 0.8, 2.5mm

9. Assessment length (ln): Ln= lr × n, n=1~5

10. Sensor:

1) Principle: The displacement differential inductance

2) Stylus: Natural Diamond, 90°, 5μm tip radius

3) Force: <4mN

4) Skid: Ruby, Longitudinal radius 40mm

5) Traversing speed:

a) lr=0.25: Vt=0.135mm/s

b) lr=0.8: Vt=0.5mm/s

c) lr=2. 5: Vt=1mm/s

d) Return: Vt=1mm/s

11. Accuracy: ±5nm+0.1A, A: Ra of calibration test block

12. Repeatability: No more than 6%

13. Residual profile: No more than 0.010μm

14. Power supply: Built-in 3.7V battery, Charger: DC5V, 800mA /3hour

15. Working Time: More than 20 hours

16. Outline dimension: 151×66×46mm

17. Weight: About 375g

18. Working Environment: Temperature: -20C ~ 40C; Humidity: <90% RH

19. Store and Transportation Temperature: - 40°C ~ 60°C

20. Humidity: <90% RH